Making sense of all of your data from all of your projects can feel like trying to understand a foreign language. But, when we break it down into steps, it starts to make a lot more sense.

- News

Schedule Quality Analysis: a Function of Project Controls

CPM schedules are the most detailed project document, containing a roadmap linking all stakeholders, their respective activities, and responsibilities. Built with integrity, a schedule can be used to constructively influence project timelines, budgets, and resource allocation. The challenge is ensuring the data is useful, which requires schedule quality analysis to avoid bad practices.

The State of Construction Scheduling (As Per the Data)

A rigorous analysis of over 50,000 CPM schedules has shed light on several areas of concern and potential improvement:

- 88% of schedules exhibit a medium to high risk of ineffectiveness.

- 90% of construction projects do not meet their schedule performance index (SPI) targets.

- 60% of schedules are compressed.

- 76% of projects show signs of delay.

The biggest risk of all? Schedule quality. The 88% at a heightened risk of ineffectiveness translates to low schedule quality, meaning a high-likelihood of data inaccuracies. These inaccuracies make the data unreliable, masking the true critical path completely. As a result, utilizing schedules to make data-backed decisions becomes out of reach.

What is Schedule Quality Analysis?

Schedule quality refers to the structural integrity of the schedule or the level at which best practices are incorporated. Schedule quality analysis, then, is the process of evaluating a schedule to ensure it is well-constructed, reliable, and adheres to best practices. This involves gauging various aspects of the schedule to ensure it is compliant with scheduling standards.

Creating Standards: Going Beyond the DCMA 14 Point Check

The DCMA 14-point check outlines 14 steps or metrics that should be assessed to ensure a schedule is high-quality.

While the DCMA’s 14-point check is an excellent baseline, it’s merely the tip of the iceberg. Projects vary based on numerous factors, from budget and scale to geography and climate. So, I’d suggest every organization dedicate some time to understanding the nuances of each risk. Look at the frequency of each metric and the impact each has on different types of builds. Luckily, your organization doesn’t have to adhere to the DCMA’s pass-fail grading structure.

To achieve this, you can add or remove certain items from their 14-point check to align schedule quality analyses with your organizational goals. For instance, you could start flagging future actual dates, resource loaded activities, or activities out of sequence. Whatever your analysis includes, the key is to maintain the integrity of the schedule throughout the project lifecycle.

How to Conduct Schedule Quality Analysis

Schedule quality analysis is not a one and done exercise. It should be assessed at every schedule update and tracked throughout the project lifecycle. This ongoing assessment ensures that the schedule remains a reliable tool for project management, accurately reflecting project progress, predicting future milestones, and highlighting potential issues before they become critical.

Step 1: Baseline Your Schedule

The first step is establishing a baseline schedule. A baseline schedule is a snapshot of your project timeline at a specific point to serve as a reference for future comparisons.

Step 2: Check for Missing Logic

Missing logic is a key driver of schedule quality because every activity (except the first and last) should have a predecessor and successor. This ensures the continuity of work. Missing logic – especially missing crew logic – can lead to inaccuracies in your schedule’s critical path and overall duration.

Step 3: Evaluate the Critical Path

The critical path is the longest path throughout the schedule, determining the project’s shortest path to completion. When analyzing your schedule for quality, ensure the critical path is realistic and that critical activities are correctly identified. This involves reviewing the logic and dependencies of critical path activities to ensure they are necessary and accurately reflect your project’s workflow.

Step 4: Analyze Activity Durations

Another common breakdown is high-duration activities because they are hard to status and can take over the critical path. So, assess the duration of activities as they get added, removed, or altered to ensure they remain realistic and achievable. Extremely long or short durations can indicate planning fallacies or confirmation bias.

Step 5: Review Constraints and Deadlines

Constraints and deadlines can significantly impact your schedule’s flexibility and critical path. Review and minimize the use of hard constraints that can artificially alter the critical path.

Automating Schedule Analysis with SmartPM

Knowing that schedule quality is paramount for other schedule controls, SmartPM’s Schedule Quality Grade™ assessment adheres to the DCMA 14-point check but allows for customization, benchmarking, and identifies critical issues and changes from the first schedule to the last. With over 35 distinct metrics, each analysis is suited to each project type, industry, and organization.

In doing so, various schedule metrics can be compared across every update. Additionally, the grading structure serves as an educational tool, promoting a better understanding of the necessity of best practices without any complicated analysis.

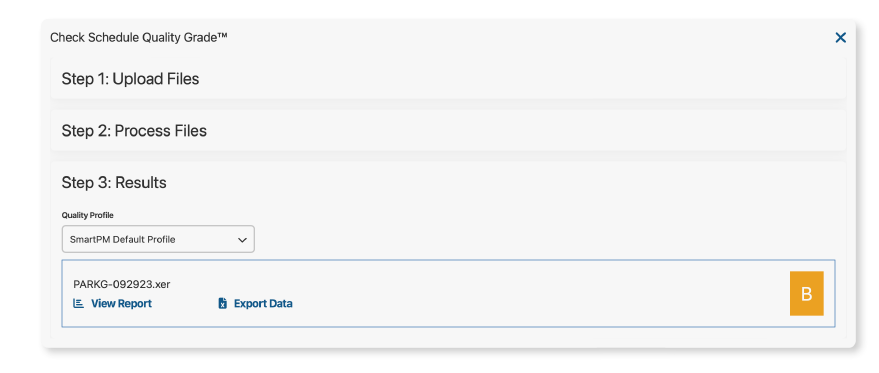

Step 1: Automate Quality Analysis

The Quality Checker automates quality analysis, helping you get your schedule files up to par before finalizing them.

Once a file is uploaded, the Quality Checker will verify if all activities are appropriately tied together, assign a letter or number grade, and deliver a comprehensive report.

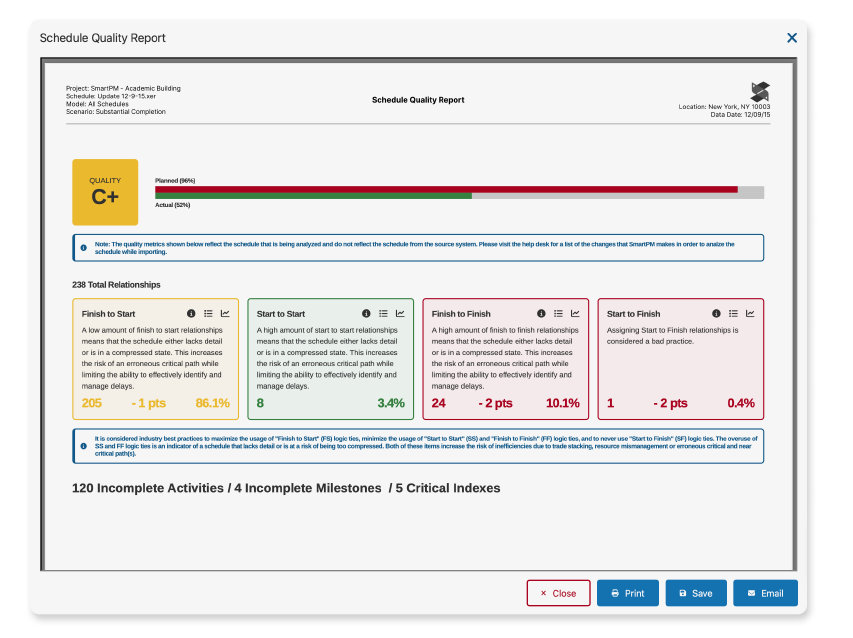

Step 2: Access a Quality Report

The Schedule Quality Report gives the details behind each Schedule Quality Grade. It explains the frequency of risk associated with every metric deemed a best practice for your organization.

Step 3: Make Your Corrections

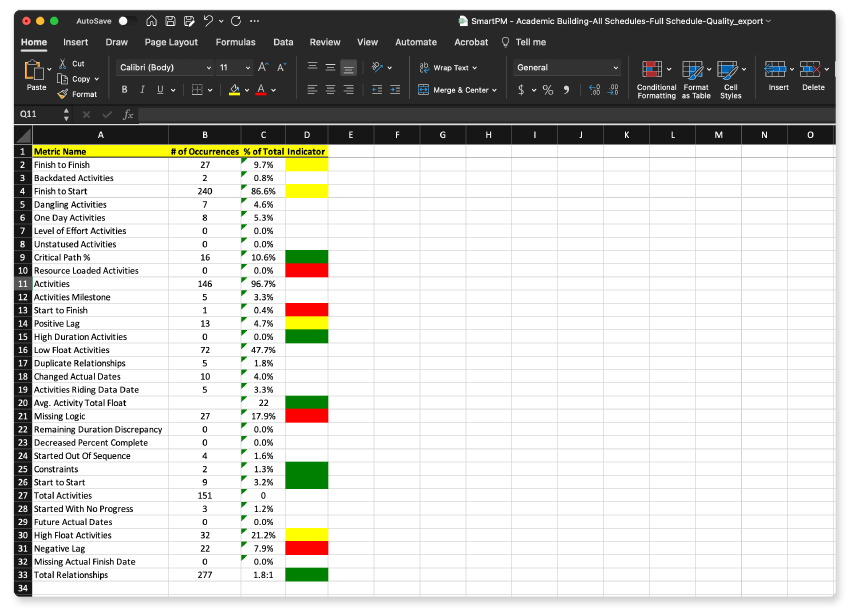

Export a Quality Spreadsheet that provides the exact changes that should be made to achieve high quality.

See every correction you need to make to ensure your project’s data is accurate and that it’s timeline is feasible after activities are added, removed, or changed from any previous update.

Why Schedule Quality Analysis is a Function of Project Controls

Project Controls allow project management to systematically and accurately measure project performance throughout the whole project by putting metrics and checkpoints in place to ensure intended progress and performance levels are being met.However, schedule quality analysis is just a fraction of project controls – but a critical part of ensuring data integrity. High-quality schedules mean the data calculated with a CPM schedule is accurate, useful, and can be used to support the decision making process.

But, achieving a high-quality schedule is just the first step. Then, you have to maintain that quality and use the data to support the control of your project outcomes. Schedule quality – just like project controls – is a constant cycle of planning, scheduling, optimizing, and repeating.

But WAIT! There’s More…

If you remember anything from this blog, it’s this: a high-quality schedule does not equal a healthy project. You have to look at various metrics, monitor, report, and communicate with your teams about what your schedule data is telling you.

After conducting the analysis, you can use your schedule data to support project controls by identifying and responding to impacts, delays, and inefficiencies of ongoing work. You can look at various indicators of project risks, such as:

- Earned Value Analysis (EVA)

- Schedule Performance Index (SPI)

- Critical Path Delay & Recovery

- Compression

SmartPM was designed to automate the above schedule analyses while ensuring that schedules are built well enough to manage a job. It also equips users with the ability to easily comprehend their data, enabling our clients to manage their project effectively toward completion. You don’t have to take my word for it either:

“SmartPM did everything we needed it to do and more. It allows us to identify potential roadblocks in our schedule and does it early enough to remediate issues. It presents information in a graphical format, allowing us to communicate a project’s status quickly and easily. And it can be used to create a high-level overview for the C-Suite executives or a deep dive for the site team.”

Ranjeet Gadhoke, Vice President of Project Controls, Zachry Construction

See the SmartPM difference for yourself. Fill out the form below to explore how our tool can simplify your project management, identify potential issues before they become problems, and improve communication across all levels of your organization.

RELATED STORIES

Making Construction Data Analytics Easier to Understand

Making sense of all of your data from all of your projects can feel like trying to understand a foreign language. But, when we break it down into steps, it starts to make a lot more sense.

Overcoming Confirmation Bias in Construction Project Management

Confirmation bias can be particularly problematic in project and schedule management, where decisions must be based on accurate and comprehensive information.

Top Construction Scheduling Software in 2023

SmartPM’s recognition as a top construction scheduling software in 2023 attests to the immense value in automated project controls.

Putting the ‘Smart’ in Project Management with Project Controls

Project controls are not just a subset of project management; they are its backbone, focusing on meticulous monitoring and analysis.